Se våra färdiga erbjudande nedan. Har du andra önskemål? Boka ett möte med våra produktrådgivare så hjälper vi dig! Logga in för att se rätt pris.

Effektiva Swadro TC 2000 - nyckeln till en effektiv foderproduktion!

Den här strängläggaren har sex rotorer som centrerar strängen bakom traktorn och har en flexibel arbetsbredd från 10 m till 19 m. Den är designad med smarta funktioner som ger rent foder till maximal kvalitet och gör jobbet enklare för efterföljande maskin. Med sin storlek och flexibilitet är den idealisk för de större fälten och dessutom kräver den minimalt med underhåll.

Den här strängläggaren har sex rotorer som centrerar strängen bakom traktorn och har en flexibel arbetsbredd från 10 m till 19 m. Den är designad med smarta funktioner som ger rent foder till maximal kvalitet och gör jobbet enklare för efterföljande maskin. Med sin storlek och flexibilitet är den idealisk för de större fälten och dessutom kräver den minimalt med underhåll.

Låt tekniken hjälpa till med att få renare foder!

Swadron är designad för renare foder och samtidigt minimera spill. Ett test utfört av DLG (Deutsche Landwirtschafts-Gesellschaft) visade att Krones Lift Tines minskar förorening av råaska i fodret oavsett arbetshastighet och dessutom minimerar de förlusterna med upp till 2,1% jämfört med andra system. Räfspinnarna lyfts i och ur arbete på ett sätt som gör att de inte riskerar att stöta i marken och förorena fodret eller skada markytan.

Timing är avgörande i ett smalt skördetidsfönster för att spara pengar!

Swadro TC 2000 har sex rotorer och en imponerande arbetsbredd, vilket gör det möjligt att bearbeta fältet fortare med bredare täckning. Dess flexibla arbetsbredd kan justeras för att möta specifika krav, vilket gör att du kan ändra bredden och arbeta mer effektivt, samtidigt som kompatibilitet med nästa maskin i processen säkerställs.

Minimerad stilleståndstid med reparationer i fält!

Om olyckan skulle vara framme är det viktigt att komma igång snabbt igen eftersom vallfodrets värde minskar varje timme med stillestånd. På Swadron kan en rotorarm bytas snabbt i fält utan en droppe oljespill, vilket sparar tid och pengar samtidigt som du inte behöver oroa dig för kontaminerat foder.

Vallskördens bästa vän är pålitliga maskiner!

Krone's Swadro-modeller kräver minimalt underhåll tack vare sina slitagefria kamspår, den hermetiskt förseglade och livstids smorda växellådan. Denna kombination minskar slitage och underhållskostnader och säkerställer att strängläggaren alltid är redo för arbete. Endast en daglig visuell inspektion och smörjning av kraftöverföringsaxeln behövs, medan andra underhållsuppgifter utförs mellan skördarna för en effektivare säsong. I Farmers First Underhållsapp finns färdiga underhållsplaner att använda som bidrar till minskad stilleståndstid, ökad livslängd och bättre begagnatvärde.

Rent foder och hög avverkning!

I mer än 10 år har KRONE Lift Tines bevisat för användare runt om i världen att det är ett ypperligt val för dem som vill producera kvalitetsfoder. Pinnarna är böjda på två ställen för att lyfta fodret snarare än att räfsa det så att det inte kontamineras. Inte ens extremt blött och tungt material böjer de 10,5 mm grova räfspinnarna. Ett test utfört av DLG (Deutsche Landwirtschafts-Gesellschaft) visade att Krones Lift Tines minskar förorening av råaska i fodret till mindre än 9% oavsett arbetshastighet och minskar förlusterna med upp till 2,1% jämfört med andra system.

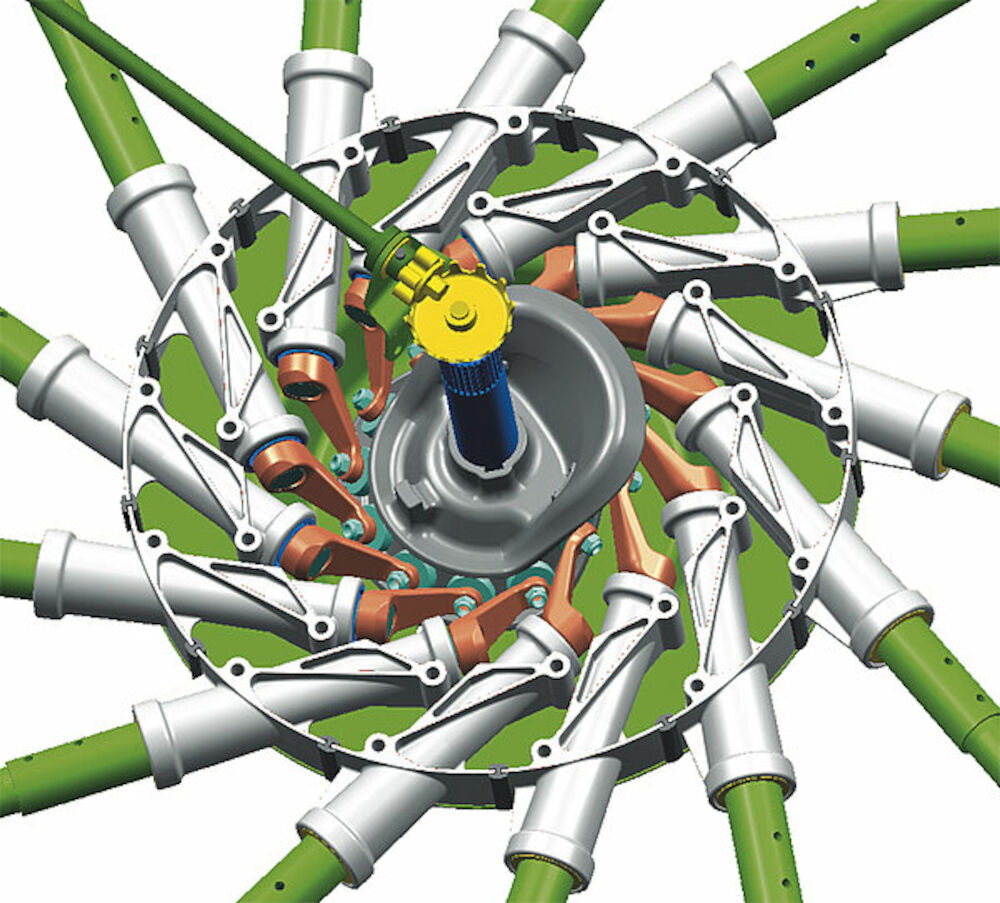

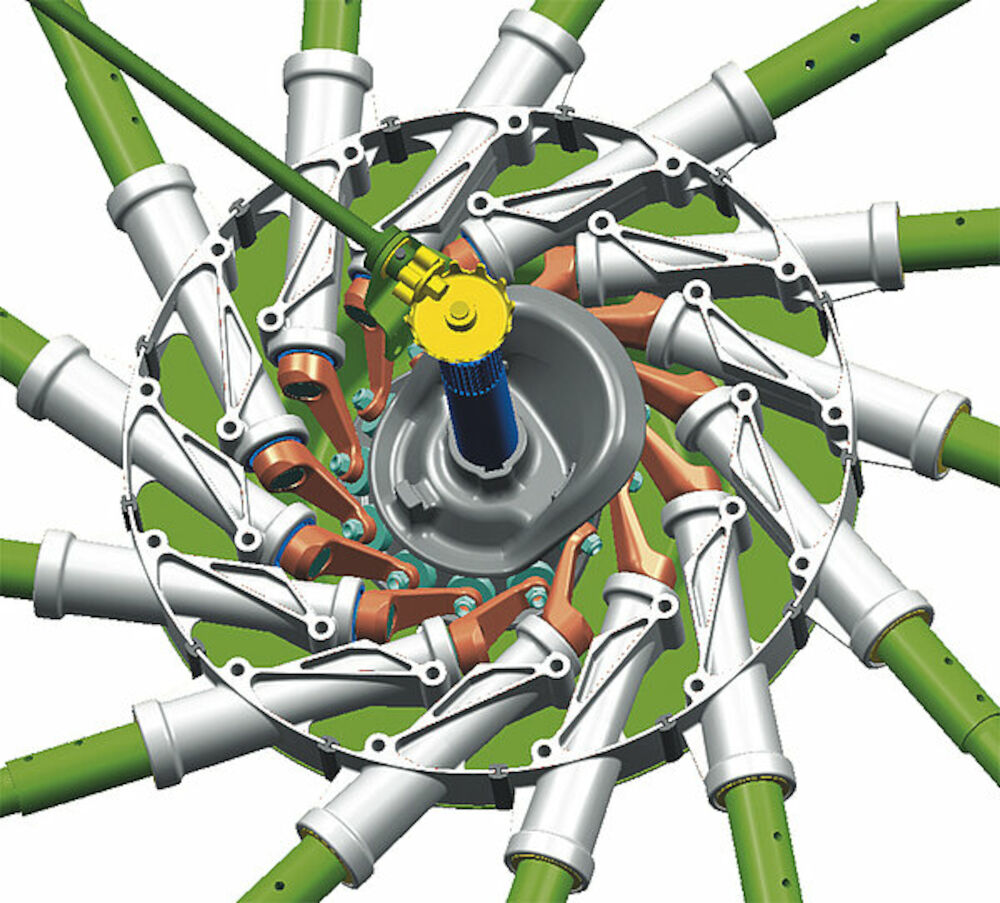

Byt räfsarm direkt i fält

Som de flesta av oss någon gång har upplevt är det lätt att böja en rotorarm när man t.ex. har bråttom. Då är det viktigt att snabbt komma igång igen eftersom fodrets värde minskar för varje timme med driftstopp. Med Swadrons DuraMax kamkurva är det möjligt att byta en räfsarm helt utan oljespill på fältet så att du kan få in fodret i tid utan att riskera kvaliteten och värdet på skörden. Kamkurvan har dessutom en speciell ytbehandling som ger låg friktion, minimerat slitage och längre livslängd.

Garanterad funktion och tillförlitlighet!

Underhållsfria och permanent smorda och tätade rotorväxellådor gör Swadron till en mycket pålitlig partner i skörden oavsett väder. Den här strängläggaren är alltid redo för arbete och säkerställer pålitlig drift i det smala skördefönstret.

-Ingen tid går till spillo på servicestopp.

-Inget smörjmedel ut = inga föroreningar in!

-Ingen tid går till spillo på servicestopp.

-Inget smörjmedel ut = inga föroreningar in!

Skonar gräsvallen och ger rent foder!

Krones Jet Effect är inspirerad av ett flygplans start- och landningsbeteende i sin rotorupphängningsdesign för att säkerställa att det alltid finns ett maximalt fritt utrymme mellan pinnen och gräsytan när rotorn sänks och lyfts ur arbete. Utan denna marginal kan skador i gräsytan uppstå och ge utrymme för ogräs att gro, som i sin tur försämrar kvaliteten på fodret. Men med Swadrons design kan skadorna undvikas, räfspinnarna håller längre och resultatet blir rent foder.

Perfekta strängar och maximal produktivitet

Med Swadro TC 2000 sätter KRONE standarden när det gäller produktivitet och strängläggnings kvalitet. Med en flexibel arbetsbredd mellan 10,00 m – 19,00 m, är areal avverkning på upp till 20 ha/h möjliga. Den enorma arbetsbredden minskar strängarnas totala längd med upp till 30 % och reducerar därför också antalet passeringar av efterföljande skördekedja per ha till ett minimum. Dessutom ökar Swadro TC 2000 kapaciteten för följande skördare med upp till 15 %. Detta gör att vallskördaren eller last- och grovfodertransportvagnen alltid utnyttjas optimalt, speciellt vid skörd med låg tillväxt.

Fyrkantiga och lätthanterliga strängar i alla förhållanden

Krones DuraMax kamkurva har en liten diameter och brant spårdesign tillverkad av specialhärdat material (bainit) som gör att rotorarmarna smidigt kan följa kurvan och lyfta räfspinnarna ur strängen snabbt och med lätthet. Detta innovativa system säkerställer att resultatet blir fyrkantiga och optimala strängar i alla förhållanden, oavsett terräng eller foderkvalitet, så att det blir enklare för efterföljande maskin att samla upp fodret.

Enastående strängläggning både i jämn och kuperad terräng

Rotorn hänger i en drag- och kardankonfiguration som säkerställer att maskinen kan röra sig i alla tre dimensionerna, vilket möjliggör optimal markföljd både i färdriktningen och tvärs över den. Med det avancerade systemet plockar räfspinnarna effektivt upp varje strå utan att få med sig ett enda sandkorn. Resultatet blir rent foder, minimala förlustnivåer och möjlighet att köra i höga arbetshastigheter.

Elektrisk arbetshöjdskontroll

Den här strängläggaren har elektrisk rotorhöjdjustering med en tillhörande display i förarhytten. Det går att förvälja 2 arbetshöjder och om arbetshöjden ändras på en rotor ändras de fem andra automatiskt till samma höjd. Det möjliggör snabb och exakt anpassning av strängläggarens höjd samtidigt som det minskar manuellt arbete, sparar tid och bränsle. Sammanfattningsvis ger den elektriska rotorhöjdjusteringen en effektiv strängläggning och minskar kostnader för jordbrukaren.

Avlastning fram och bak med Krone Easy-Line

KRONE Easy-Line drivkoncept innebär;

- Ett kontrollerat materialflöde genom maskinen för bästa möjliga strängläggning

- Medger ökad produktivitet hos balpressen, snittvagnen eller fälthacken

- Inga tvinnade strängar för bästa maskinprestanda hos efterföljande skördemaskin

Enkel inställning för att passa olika skördeförhållanden

Både arbetsbredden och strängbredden kan ställas in hydrauliskt från hytten för att vara optimalt anpassade för förutsättningarna. En bredare arbetsbredd kan exempelvis lämpa sig under andra eller tredjeskörden för att spara tid på fältet, medan en smalare arbetsbredd kan vara bra för att inte en för stor mängd foder ska matas in i efterföljande maskins pick-up och sättas igen. På så sätt kan du anpassa maskinen till olika förutsättningar på kort tid!

Smidig och säker transport med lägre transporthöjd!

Chassit på Swadro TC har imponerande vägstabilitet och enastående svängradie som är godkänd för hastigheter upp till 40 km/h. Genom snabba omställningar minskar transporthöjden till under 4 meter, räfsarmarna viks ihop istället för att demonteras och de teleskopiska armarna dras in för att minska maskinens höjd.

Smidig motstyrning för de tajta svängarna och på sluttande fält

Med ett extra hydrauliskt system för att kontrollera motstyrningen på stängläggaren blir det enklare att köra igenom tajta svängar och att hålla raka linjer i sluttningar på fältet. Det är en hydraulcylinder på styrsystemet som justerar svängvinkeln eller positionen bakom traktorn så att även smala passager genom grindar gå smidigt, trots dess storlek. När rotorerna tas ur arbete aktiveras den passivt styrda hjulaxeln automatiskt för att styra chassit via en stång vilket kortar ner tiden för vändningar.

Flexibelt Ackermann-styrsystem

På transportchassit kan Ackermann-styrsystemet användas på två olika sätt: antingen passivt genom en länkarm eller aktivt via en hydraulisk cylinder. Utmärkt svängradie, förmåga att manövrera i trånga utrymmen och enkel styrning är egenskaper som beskriver detta chassi.

Lägre marktryck med stort transportchassi

Med stora 800/45 R 26.5 däck för god vägstabillitet är transportchassit godkänt för vägtrafik i 40 km/h. Dessutom hålls marktrycket lågt och gräset skyddas hållbart. Den robusta och rörliga nedre draganordningen är i kategori II/III kompenserar för ojämn mark och har ett stabilt stödben som används vid parkering.

Anpassa strängbredden till efterföljande maskin

Det är inte bara möjligt att anpassa arbetsbredderna efter behov utan även strängbredden går att anpassa. Detta görs genom att hydrauliskt och steglöst justera de bakre rotorerna mellan 1,60 m och 2,80 m vilket är förinställt på terminalen. Tekniken hjälper till att forma perfekt fyrkantiga och högvolymsträngar för efterföljande skördemaskin. Bredden mellan de yttersta rotorerna är 10 till 19 meter, vilket dessutom gör det enkelt att anpassa mängden foder som läggs i strängarna. På så sätt blir mängden foder i varje sträng lagom mycket oavsett strängbredd och om det är första eller sista skörden på säsongen.

Automatiska hopfällningsfunktionen

Med den smidiga automatiska hopfällningsfunktionen hanterar en hydraulisk sekvensstyrning alla steg åt dig, vilket gör arbetet enkelt och smidigt.

Sektionskontroll som avlastar vid kilformade områden

Sektionskontrollen detekterar områden som man redan har stränglagt och höjer automatiskt rotorerna för att inte köra på samma ställe två gånger. Detta avlastar föraren och gör det enklare att hantera kilformade områden. För att kunna använda sig av sektionskontrollen behöver traktorn ha GPS med funktionen sektionskontrol (SC).

Driftterminalerna CCI 800 och 1200

Med driftterminalerna CCI 800 och CCI 1200 erbjuder KRONE två ISOBUS-kompatibla pekskärmsterminaler med en färgdisplay på 8" eller 12". Förutom huvudskärmen kan upp till två andra skärmar visas växelvis. Till exempel är det möjligt att växla mellan tilldelningen av joystick, delbreddssektionell styrning eller en kamerabild under arbete.

Terminalen DS 500

Den kompakta terminalen DS 500 har en färgdisplay på 5,7". Driften sker antingen via de tolv funktionsknapparna eller via pekskärmen enligt förarens behov. Användningen av ISOBUS-joystick gör driften ännu bekvämare. Detta avlastar föraren på bästa möjliga sätt, framför allt under långa arbetsdagar.

-

Typ av maskin Bogserad centrumläggande rotorssträngläggare med 6 rotorer

-

Strängposition Centrum

-

Effektbehov 130 hkr

-

Effektbehov 96 kw

-

Arbetsbredd 10,00-19,00 m

-

Strängbredd max. 2,80 m

-

Strängbredd min. 1,60 m

-

Transportbredd 2,99 m

-

Transporthöjd 3,99 m

-

Transportlängd 13,20 m

-

Vikt 940000 kg

-

Tillkoppling och kategori Bakre hydraularmarna

-

Tillkoppling hydraulik (DA=dubbelverkande, SA=enkelverkande) LS/ 1xSA+fri retur

-

Transportchassi

-

Bromsad axel Ja

-

Antal rotorer 6

-

Rotordiameter 3,30 m

-

Antal rotorarmar/rotor 4x13, 2x15

-

Antal räfspinnar/rotorarm 4

-

Räfspinnarnas grovlek 10.5 mm

-

Justering arbetshöjd Elektriskt med display

-

Justering arbetsbredd Hydrauliskt

-

Däck rotorhjul 16x6.50-8

-

Däck transporthjul 800/45 R26.5 174D TL

-

Färdljus

-

ISOBUS-kompatibel

-

Terminal Som tillval

Allmänt

Dimensioner

Ram & tillkoppling

Rotorer

Kontrollsystem

Hjul

Elektronik

I över 100 år har KRONE varit en pålitlig tillverkare av moderna vallmaskiner från Tyskland. Idag består deras sortimentet av premiummaskiner för grovfoderskörd, däribland pressar, slåttermaskiner, hövändare, strängläggare, fyrkantsbalpressar och självgående exakthackar.

KRONE är ett familjeägt företag som levererar pålitliga, högkvalitativa och hållbara maskiner med målet att öka kundens produktivitet. För servicepersonalen har de ett gediget utbildningsprogram och en stor databas som gör det enklare att supportera i en felsökning.

KRONE är ett familjeägt företag som levererar pålitliga, högkvalitativa och hållbara maskiner med målet att öka kundens produktivitet. För servicepersonalen har de ett gediget utbildningsprogram och en stor databas som gör det enklare att supportera i en felsökning.