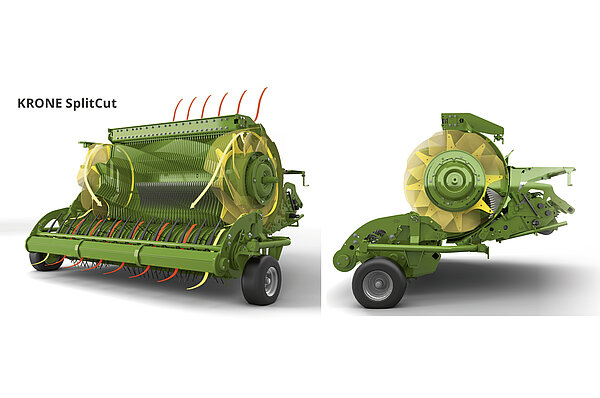

Their proven-and-tested design features and innovative technologies, such as the KRONE SplitCut edge cutting system and the OptiGrass concept, make the RX dual-purpose loading and forage transport wagons the ideal machine for efficient harvesting. With a loading volume of 33, 37 or 40 m³, these loading and forage transport wagons offer ample capacities for successful forage harvesting.

High efficiency and versatility

The RX wagons offer a cost-effective and versatile solution for your forage production. These wagons are designed to handle both grass harvesting and crop transport, providing you with flexibility and faster workflows. With RX wagons, you no longer need to switch equipment between different harvest seasons, saving both time and resources.

Impressive load capacity

The RX forage wagon can handle large volumes of forage, increasing your productivity and reducing the need for multiple trips. The adaptable front wall allows for maximum filling, whether it's filled through the pickup or from a precision chop. With various convenient unloading options, you can quickly and efficiently empty the wagon at different locations.

Efficient processing and precision cuts of all material

The forage wagon features a high-performance, high-capacity pickup that smoothly adapts to the terrain. It is equipped with reliable double 6.5 mm pins and an impressive working width of 2.125 meters. The grass is fed from the sides into the cutting unit, which delivers scissor-like precise cuts, ensuring that all material is processed correctly. Optionally, it can be equipped with a knife sharpening system, which allows for easy and quick restoration of the knives' sharpness on-site in less than 4 minutes.

Functions as a self-loading forage wagon

The wide pickup, spacious feeding chamber, and hydraulically pivoting front wall ensure fast and even filling to maximum capacity. For superior cutting quality (scissor-like cuts), the distance between a knife blade and a rotor finger is minimal.

The ideal collection wagon

With capacities from 33 m³ to 40 m³, the ZX models make perfect collection wagons that empty the material extremely quickly. This dual functionality makes the RX an even more productive machine.

Maximum crop flow

The EasyFlow pickup ensures maximum crop flow with reliable and efficient dual 6.5mm tines. The pivoting pickup is known for efficiently clearing the field even under challenging conditions. With a working width of 2,125 meters, it allows you to work at a high pace, resulting in high hourly production. EasyFlow smoothly adapts to ground contours with swiveling support wheels and has an upper-mounted swath roller that compacts large, tall swaths for efficient collection. Height adjustment for different crops and conditions is quick and easy, and the two flexible wheels smoothly follow curves to ensure nothing is missed.

Optimal ground following

The EasyFlow pickup is equipped with a nitrogen damper that provides electro-hydraulic suspension for the pick-up. This protects your soil and allows you to adjust the suspension pressure directly from the cab, even during operation. In uneven terrain, the EasyFlow pick-up pivots around the core of the cut-and-feed rotor, ensuring a smooth flow of material into the machine, regardless of the terrain conditions. The pick-up can move both axially and laterally, following the contours of the ground with pneumatic guide wheels on each side. Optionally, additional guide wheels can be mounted on the rear of the pick-up, providing even better ground following in soft and wet soil. This offers excellent maneuverability when following the tractor during turns and ensures optimal protection for the soil surface.

Generous ground clearance

The pickup has a generous ground clearance of up to 75 cm and can be preprogrammed for different positions, allowing for quick adjustments in the field. Additionally, it features an integrated hydromotor that reduces maintenance needs and allows for a wider working width. For the smoothest material flow, the speed can also be adjusted manually or automatically depending on ground speed and conditions.

First-class cuts with OptiGrass!

This cutting unit is designed to deliver outstanding cutting speed and quality. Choose the number of knives to customize the theoretical cutting length: 54 knives provide 28 mm and 40 knives provide 37 mm. The clean, scissor-like cuts ensure precise cutting lengths as the rotor fingers force the forage through the cutting unit's knives with precision. This precision cutting prevents the forage strands from bending before cutting, which can result in uneven and longer cuts.

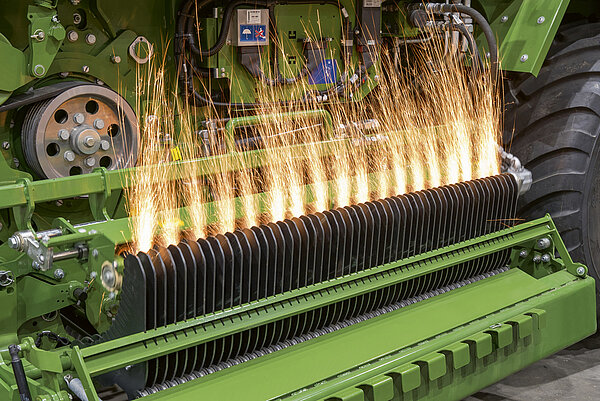

KRONE SplitCut – optimally chopped forage across the entire working width

A concept that, thanks to its innovative design, enables feeding across the entire rotor width. Composed of a knife blade, a partition, cleaning pins, and a guide plate for the fed crop, the two SplitCutter units ensure that crop parts on the outer edges of the crop flow are returned to the center of the flow. This ensures that each stalk has completely passed through the cutting unit, resulting in perfect processing quality and that the entire crop flow is truly chopped.

Drive longer with KRONE Powerbelt

Maximize throughput and loading speed with minimal errors, even in uneven swaths and varying crops. KRONE Powerbelt cushions short-term load peaks, prevents overloads, and ensures you can keep running while others are standing still. In the spring, when larger swaths require higher rotor speed, the larger pulley is placed at the front and the smaller one at the back to achieve a rotor speed of 47 rpm. In late summer and autumn, when the rotor speed doesn't need to be as high, the smaller pulley is placed at the front and the larger one at the back to achieve 40 rpm.

Integrated knife protection

To ensure trouble-free operation, all knives have individual spring-based protection. This means that if your machine picks up something unwanted, the knives will move back to their working position once the foreign object has passed. This technology is not only simple but also effective, enhancing operational safety. Release force can be centrally and continuously adjusted.

Quick and easy knife changes

The knives have long, curved cutting edges that provide fuel-efficient cuts as the forage passes by them. Their serrated edges cut all types of forage with precision and maintain sharpness for longer. All knives in the cassette are identical and can be quickly replaced for easy maintenance. To insert or remove the knives, simply lower the knife cassette hydraulically and swing it to the side. After unlocking the knives with a central lever, they can be easily removed and replaced.

Fast and efficient knife sharpening with SpeedSharp! (Optional)

With the optional fast and convenient on-site knife sharpening, it takes less than four minutes to sharpen 48 knives. You achieve consistent and high-quality sharpening, reducing fuel consumption and improving forage quality. It is also possible to adjust the blade grinding interval on the terminal to adapt the intensity to the actual level, which yields better results.

Up to 4.5 m³ of additional loading space with pivotable front wall

The forage wagon's pivotable front wall is a feature that can be controlled manually or hydraulically to simplify loading, whether you're using it as a collector wagon or a forage wagon. With the front wall in the lowered position, it compacts the forage to maximize loading capacity. When the wagon is full, it's detected by a sensor, and the front wall folds back to create an additional 4.5 m³ of space for forage. Moreover, it aids in emptying the wagon quickly, making it efficient for handling large crop volumes.

Robust chain and slat floor

The robust chain and slat floor in the forage wagon ensures that even heavy forage is quickly and evenly fed backwards for unloading. This durable and reliable system can withstand tough conditions and ensures that your load is handled smoothly. The inclined floor increases capacity and reduces the length of the feed passage, leading to faster and more gentle feed supply as well as reduced power consumption.

Long longevity and robust construction

To ensure long lifespan, KRONE RX wagons are equipped with a durable steel floor. The floor slopes towards the cutting and feeding rotor, ensuring smooth operation and minimizing wear, while the flat link chains contribute to powerful progress with minimal wear. Additionally, with dual scraper floor conveyors for efficient unloading and a robust construction with a tapered design, smooth emptying and long-lasting durability are guaranteed.

Convenient access through the door

This forage wagon have a spacious side door that provides easy access to the loading area. You can easily climb up the foldable ladder with a handle on the side for safe ascent.

Look good with premium lighting package as standard

The lighting on the KRONE RX provides optimal visibility and safety both day and night with a standard premium lighting package. Two powerful LED work lights at the rear offer excellent all-around visibility even in nighttime conditions. Forward-facing position lights and reflectors ensure safety in the field and on the road. Inside the cargo area, LED light strips keep the load visible and facilitate work even in the dark. For extra lighting, two additional work lights can be easily installed thanks to the prepared cable positions. The premium lighting package enhances safety and increases productivity during night work through optimal illumination. More work lights can be retrofitted for additional customization.

Additives for silage (optional)

This forage wagon features an integrated dosing system for silage additives with a 200-liter tank for additives. The dosing system applies the additive through flat spray nozzles above the intake device and is easy to clean. The pump unit can be removed without tools for maintenance, and operation control is conveniently done via the terminal. An electronic level indicator provides reliable monitoring of the additive supply.

Oil supplied only when needed

The comfortable hydraulic system is compatible with load-sensing systems, meaning that if it is connected to a load-sensing hydraulic system, oil will only be supplied when needed. This intelligent system reduces the load on the tractor's hydraulics and optimizes resource efficiency. For tractors without load-sensing systems, it is still possible to use the machine with an Open Center system, providing flexibility and versatility in use.

Cover curtains (optional)

The optional cover curtains conform to the shape of the feed mass and effectively cover the material without the risk of opening at high speeds. Controlled by hydraulic motors, the cover curtains are managed with quick and reliable control. The open cover curtains hang along the side of the wagon so as not to be in the way while the wagon is being filled.

Electronic crop weighing system (optional)

The available weighing system is a practical solution that utilizes load cells on the chassis and the articulated drawbar to accurately determine and log the weight of the load. With this system, you can easily weigh the crop and obtain precise weight measurements, simplifying your workflow and providing better control over transportation.

SmartConnect (optional)

It is possible to equip the forage wagon with a KRONE SmartConnect telemetry unit. This interface serves as a basis for data management with GPS and WLAN capabilities. It simplifies the tracking of the transport wagon's current location. All essential data is also automatically recorded and can be quickly sent to the office.

Camera (optional)

An optional camera is available for this model. The image is displayed on the color screen to enhance visibility and safety.

Ideal for heavy loads and long transports

The RX 400 comes standard with a hydraulic 20-ton tandem chassis, with the option to upgrade to a hydraulic 27-ton tridem chassis. The narrow and compact drawbar, along with the articulated drawbar providing a high lifting height, makes the RX 400 ideal for handling varying harvest conditions and challenging situations at the silo. Intelligent self-steering is standard, while contactless electronic forced steering is offered as an option.

Electronic forced steering

Electronic forced steering is available as an option for tandem axles and is standard for tridem axles. It offers smooth and quiet operation with low wear, ideal for maneuvering. This system can be manually operated for countersteering and protects the ground surface and tires during turns, reducing strain on the axles. It provides superior driving stability and safety at high speeds and automatically adjusts steering intensity based on the machine's forward speed. This contactless electronic forced steering system enhances maneuverability and safety during operation, particularly near the edges of feed plates or on the road.

Operator terminals for increased efficiency

Operator terminals are designed with user-friendliness in mind, offering straightforward and clear navigation.

- DS 500 terminal: A compact terminal with a 5.7-inch screen that provides easy control of up to 12 functions.

- CCI 800 and CCI 1200 operator terminal: With an 8 or 12-inch touchscreen that can be split into two views, it offers the same functions as the Delta terminal.

- Existing third-party terminals: If your tractor already has an ISOBUS terminal, you can use it to control the ZX system.

Operators comfort

The comfortable electronic system is compatible with ISOBUS and is necessary for optional features such as the automatic loading/unloading system. This system enhances driver comfort by integrating and simplifying the use of various functions, making the workflow smoother and more efficient. With ISOBUS compatibility, the operator can take advantage of advanced features and increased control over the loading and forage transport wagon.

Minimal maintenance work

The forage wagons are prepared for the integration of a central lubrication system where lubrication intervals can be controlled and adjusted from the cabin. To make maintenance smooth, it has few lubrication points, saving both time and money in maintenance work. Additionally, there is ample space to clean the wagon after operation, thanks to the adjustable chassis height, which provides higher ground clearance.

-

Type of wagon Forage wagon

-

Tractor power 175 hkr

-

Tractor power 130 kw

-

PTO speed 1000 rpm

-

Ground clearence 75 cm

-

Width 2,98 m

-

Height 3,95 m

-

Length 10,06 m

-

Plattform height 1,57 m

-

Permissible axle loads (with tandem unit) 24000 kg

-

Permissible axle loads (with tridem unit) 31000 kg

-

Hitch 80 mm ballhitch, articulated with suspension

-

Max drawbar load 4000

-

PTO, shaft Driveshaft with wide angle joint on one end, 1 3/4", Z=20 incl. overload clutch

-

Hydraulic couplers, tractor LS or auxillary couplers 3xDA

-

Crop feed width 2,12 m

-

PickUp Camless pick-up EasyFlow (work width 2,125 mm according to DIN 11220), tines arranged in a W-shape (tines spaced 55 mm apart), height adjustable pivoting guide wheels 16x6.50-8

-

Cutting unit

-

Type of cutter PowerBelt drive, OptiGrass cutting unit rotor-integrated planetary gearbox, swap pulleys for implementing speed changes Power-saving cut-and-feed unit with 8 rows of tines plated with wear-resistent Hardox steel SplitCut edge cutting system

-

Number of cutting knives, std (option) 40 (54)

-

Cutting length, std (optional) 37 (28) mm

-

Volume loading area 40 m3

-

Discharge rollers

-

Tandem wheel axle as standard

-

Tridem Optional

-

Tyresize standard 800/45 R 26.5 TL

-

Wheel size, options 800/45 R 26.5 Trac, 710/50 R 30.5, 800/45 R 30.5 Trac

-

Track width 2,05 m

-

System KRONE comfort on-board electronics system

-

ISOBUS compatible

-

Terminal Optional

-

Hydraulic system LS or OC

-

Cross conveyor unloading

-

Load cover Optional

-

Knife sharpening system onboard Optional

-

Knife sharpening device, specification Automatic SpeedSharp blade grinder

General

Dimensions

Frame

Feeding

Loading area

Wheels

Attached implements

For over 100 years, KRONE has been a reliable manufacturer of modern forage machinery from Germany. Today, their product range includes premium machinery for forage harvesting, including balers, mowers, tedders, rakes, balers, and self-propelled forage harvesters.

KRONE is a family-owned company that delivers reliable, high-quality, and durable machinery with the goal of increasing customer productivity. They provide extensive training programs for their service personnel and maintain a large database to simplify troubleshooting and support.