Report - Safe Maintenance

Safe maintenance in agriculture

In the EU27, family work and a high degree of self-employment dominate the agricultural industry, as most of the work on farms is carried out by the farm owner and his or her family. Nine out of ten people working on farms (89%) are family workers [1]. In 2007, about 78% of farmers worked alone with the help of family members and temporary help from employees brought in during peak seasons [2].

Agriculture is a sector that has a higher proportion of workers on temporary contracts (43.9%), compared to an average of 16.7% for all sectors, and the highest proportion of employees working without contracts (24%) [3].

Agriculture is also characterized by relatively high levels of unskilled labour. Education levels are relatively low; most workers in the sector have lower levels of education or no education at all [3]. The Health and Safety Executive (HSE) in the UK reported that in 2000, 22% of agricultural managers had either basic or full agricultural training, but the majority had only practical experience. This applies especially to those who work on small farms [4].

Typically, the agricultural sector employs seasonal workers and contractors during busy periods (for plowing or harvesting). Contractors are often used for particularly hazardous jobs such as cleaning or repairing fragile roofs or cleaning manure tanks [5] and are at greater risk of accidents and illnesses. In the agricultural sector, seasonal workers are often migrant workers [6]. Lack of awareness of dangers and risks and language difficulties make migrant workers vulnerable to accidents and diseases.

Hazards related to maintenance in agriculture

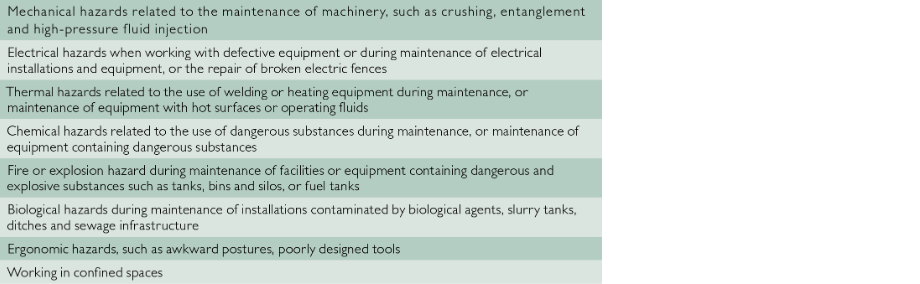

The maintenance activities in agriculture are very varied. They include maintenance and repair of machinery, equipment and vehicles, maintenance of farms and buildings, silos, bins and tanks, maintenance of electrical installations, and maintenance of drainage and irrigation systems and roads. Due to the wide variety of farm maintenance tasks, there are many different hazards involved. Some of them are listed in table 1.

But there are other factors that contribute to the high number and severity of accidents. Farmers often do a lot of maintenance work themselves. This increases the risk of accidents because, on the one hand, the farmer may lack competence in specific maintenance tasks and, on the other hand, agricultural machinery and vehicles are becoming more and more sophisticated, which requires qualifications in maintenance and repair.

Farming often involves people working on their own. When a blockage occurs or a vehicle breaks down, the repair can be carried out by a single worker. Working alone not only increases the risk of an accident, but also means that in the event of an accident, its severity can be amplified as the injured worker may not only be alone but also in a remote location.

Many agricultural workers are self-taught. Many have only practical experience and no professional agricultural training. Agricultural maintenance involves multiple tasks that are often seasonal and take place in a variety of locations from the workshop to the farm to the field. Agricultural maintenance workers are expected to be able to switch from one type of equipment or tool to another, depending on the needs. This makes professional agricultural training very difficult and as a result most farmers are usually trained "on the job". Financial constraints and considerations can determine the course of action a farmer will take in terms of maintenance. For example, to save money, a farmer may make makeshift repairs using substandard components, tools and PPE, and may be reluctant to

hire professional maintenance and repair services. Time pressure can lead to the worker carrying out a temporary repair with inappropriate tools and equipment. Farm workers often do not use personal protective equipment, such as safety harnesses to prevent them from falling through, or from roofs.

What can be done to make maintenance work on farms safer?

As the operations within agricultural maintenance are very different, so are the risks. Therefore, it is important to use several different strategies to reduce the probability of events. Some effective methods are listed below.

Prevention by design – eliminate hazards already at the design stage!

One of the best ways to prevent and control occupational hazards related to maintenance is to address them early in the design process of buildings and structures, work environments, materials and facilities (machinery and equipment). The maintainability of agricultural machinery and vehicles affects maintenance safety and helps minimize MSD risks and should be considered at the design stage. Good maintainability means, among other things, that all points for routine maintenance are easy to access, such as lubrication points, engine and battery, service and maintenance intervals are longer, etc. Poor maintainability can reduce maintenance safety, it lengthens work tasks and makes work more complicated, all of which can increase the risk of accidents. Good design can prevent accidents if it makes it difficult or impossible to perform a maintenance task incorrectly or in an unsafe manner.

Maintenance of machines and vehicles

The machine/vehicle must be switched off before intervention, maintenance or service, and it must be ensured that it has stopped. Parts that can move or rotate must be secured, e.g. by using blocks, equipment. Manufacturers' instructions should be followed. Protection must be removed before restarting the machine.

Work in tight spaces

Farm workers may need to enter confined spaces such as damp grain silos, manure pits or storage bins to perform maintenance, inspection, cleaning and repair. Hazards can arise from lack of oxygen, toxic or flammable gases, liquids and solids that can suddenly fill the space and cause suffocation, drowning, fire or explosion. Entering confined spaces should be avoided if possible. If entry is unavoidable, adequate equipment, such as personal protective equipment (eg, respirators, harnesses and safety lines), lighting (approved for explosive atmospheres) and communication equipment should be used and the air must be tested before entry. Appropriate emergency situations must be introduced. Persons performing maintenance in confined spaces should have adequate training and experience. Good design, including the design of openings, covers and fasteners can improve diagnostics and accessibility for maintenance operations.

Work at heights

Maintenance of buildings, structures and machinery on farms may involve working at heights. Falls often occur from roofs or through fragile roofs, from vehicles, ladders and inappropriate access equipment. If work at height cannot be avoided, appropriate access equipment must be used and fall protection equipment, such as safety harnesses, if necessary. Buildings that have fragile roofs should be provided with warning signs, especially at access points. When using ladders, you must ensure that the ladder cannot slide and that it has a flat and stable surface.

Information and education

Information and education are needed to reduce the number and severity of accidents and occupational diseases suffered by farmers and people who work on farms. However, they are difficult to reach because farms are often run as family businesses and there are a large number of self-employed people in the sector. Farmers are used to deciding for themselves how to carry out their work and deal with problems. They tend to place a high degree of trust in their own experience. It is therefore important to involve them and to include their experiences in all activities aimed at improving occupational safety.

Maintenance of buildings, structures and machinery on farms may involve working at heights.

In the transport sector, analysis of various health and safety campaigns has shown that drivers can be most effectively reached using [7]

- Face 2 Face discussions

- Training and advice on site

- Events involving their families.

This is likely to be equally true for agricultural workers, and a successful strategy to reach this group may be to offer on-site training with practical experiences so that the training is relevant to everyday tasks and takes into account the specific problems of farmers. If possible, information and training should be provided by other farmers (approved by the farmer) and given at a location where the farmers feel comfortable. This approach was adopted by the HSE for their 'Farm Safety and Health Awareness Days' (SHAD) in the UK event, and has received positive feedback from the majority of farm workers who have attended the programme.

Events such as agricultural fairs or farm women's meetings can provide a very good opportunity to reach the farmers and their families directly and to motivate them to participate in the training by promoting face to face discussions. It can be assumed that involving the family can help to reach and motivate more workers.

* More information

To find out more about safe maintenance in agriculture read the web publication "Maintenance in agriculture – a safety and health guide" available at http://osha.europa.eu/en/publications/ reports/maintenance-inagriculture- a-safety- and health guide.

»»References ››1. Eurostat, Agricultural statistics: Main results 2007–08, Eurostat Pocketbook, 2009 edition. http://epp. eurostat.ec.europa.eu/cache/ ITY_OFFPUB/KS-ED-09-001/ EN/KS-ED-09-001-EN.PDF. ››2. Eurostat, Farm structure, statistics explained (March 2010). http://epp.eurostat. ec.europa.eu/statistics_explained/index.php/Farm_structure. ››3. Eurofound, Factsheet: Agriculture and Fishing, Luxembourg, Office for Official Publications of the European Communities, 2008 ›› http://www.eurofound. europa.eu/pubdocs/2008/141/sv/2/EF08141EN.pdf. ››4. United Kingdom Health and Safety Executive "About health and safety in agriculture", 2010, available at http://www.hse.gov.uk/agriculture/hsagriculture.htm. ››5. Health and Safety Executive Northern Ireland, 'The guide to health and safety in agriculture', 2001, available online at http://www. healthandsafetyworksni.gov. uk/guide_to_health_and_safety_in_agriculture-2. pdf. ››6. Eurofound 'Employment and working conditions of migrant workers', 2007, p74, available online at http://www.agri-migration.eu/docs/ployment%20and%20 work%20cond%20eurofund. pdf. ››7. EU-OSHA, "Delivering the message – Programs, initiatives and opportunities to reach drivers and SMEs in the road transport sector", 2011 http://osha.europa.eu/ en/about/Road-transport/ report_delivering-themessage. pdf.

KATALIN SAS

KATALIN SAS