MX TX400 series frontloaders consists of 3 frontloader models for tractors with engines over 170 hp. MX TX 400 is manufactured in France.

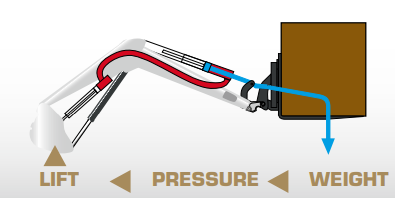

Smooth operation with hydraulic parallelogram

The patented Hydraulic Compensation Parallelogram (HCP) provides extra power and a stable implement angle when raising and lowering the loader. The HCP system enhances performance by handling heavier loads without compromising stability. It reduces the need for adjustments, saves time and energy, and ensures smooth and reliable operation for repetitive tasks with high precision.

An arm structure that exudes both strength and durability

The arms are constructed from two welded "U"-shaped profiles, made from 6 mm thick HLE steel. With an assembled width of 100 mm, this design offers unmatched durability and resilience to handle the toughest tasks on the farm, day after day.

Enhanced visibility, safety and comfort

The HCP is positioned under the loader, ensuring a clear view of the surroundings from the cab. This not only improves safety but also reduces driver fatigue and promotes comfort during long work shifts. Additionally, the lifting rams are positioned higher on MX loaders than on comparable loaders, creating a larger gap down to the mud guard, eliminating any risk of collision between them.

Powerful and maintenance-free hoist cylinders

This front loader features lift cylinders that deliver impressive power. The cylinders are connected with heavy-duty pipes that protect against impacts and shocks, reducing maintenance costs throughout the loader's lifespan.

Implement carrier with automatic locking/unlocking

The TX loader features a specific implement carrier with FAST-LOCK hydraulic locking as standard. This automatic locking and unlocking system makes changing implements quick and easy, saving both time and effort. Depending on the model you choose, you can also attach implements designed for telescopic forklifts, providing exceptional versatility for handling various tasks on the farm.

Robust and durable pivot points

This front loader is equipped with ARCOR-treated pins that provide exceptional wear resistance. Protected grease nipples ensure that maintenance is simple and efficient, while bushes with a lubrication system keep everything running smoothly. Additionally, there is a pin plate anti-rotation locking system, which further enhances the stability and longevity of your front loader.

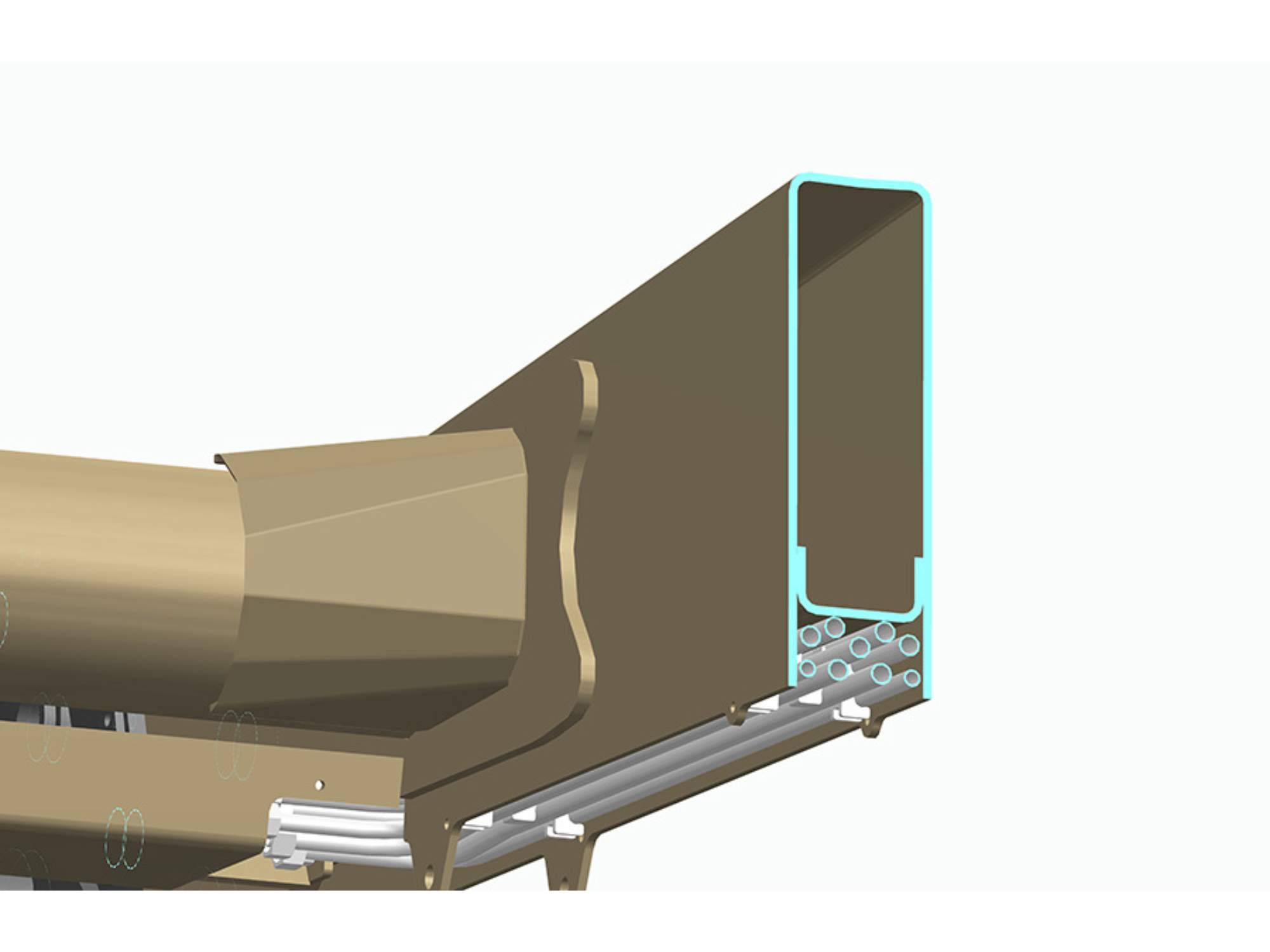

Hydraulic units protection

The front loader is equipped with high-quality hydraulics and excellent protection. All hydraulic parts are integrated into the arm for better visibility and impact protection. The hydraulic system, including suspension and additional functions, is protected by a double casing on the loader's crossbeam. Standard features include two shock protection valves, durable nylon-coated hydraulic hoses, and polyurethane-protected wiring. The robust construction withstands extreme outdoor conditions, ensuring top performance on the farm.

Effortless unloading with AUTO-UNLOAD

AUTO-UNLOAD allows for combined movement using the E-PILOT S thumbwheel, enabling easy unloading where the grab opens and dumps simultaneously. This makes it easier to save time and gives you the peace of mind for repetitive actions. With this feature, MX not only enhances efficiency but also simplifies tasks, ensuring smoother operations and happier operators.

Automated leveling streamlines operations

The AUTO-LEVEL by MX is a game-changer in efficiency. This feature offers automatic implement position rest, allowing implements to be effortlessly repositioned to a pre-selected position. By automating the leveling process, MX enables operators to focus on other tasks, streamlining operations and reducing fatigue. With AUTO-LEVEL, precision and efficiency go hand in hand, ensuring optimal performance with minimal effort.

Since 1951, MX has been supporting farmers by making their work easier. As France's largest and Europe's second-largest manufacturer of tractor loaders, they are represented all over the world. Their extensive product line includes loaders, control systems, handling tools, distribution tools, feeding equipment, weights, bumpers, front-mounted couplings. Regardless of your business, MX offers customized solutions that can be tailored to your needs.