Since 1985, the Dutch company GKB has developed user-oriented and innovative machines that are adapted to all types of sports surfaces. Do you have a natural grass sports field or golf course where surface water causes a problem? Does the field remain wet for too long, making you fail to achieve the desired playing hours? And do you have a lack of time or budget to support a complete renovation? With the Drainmaster we offer the ultimate machine to tackle these problems.

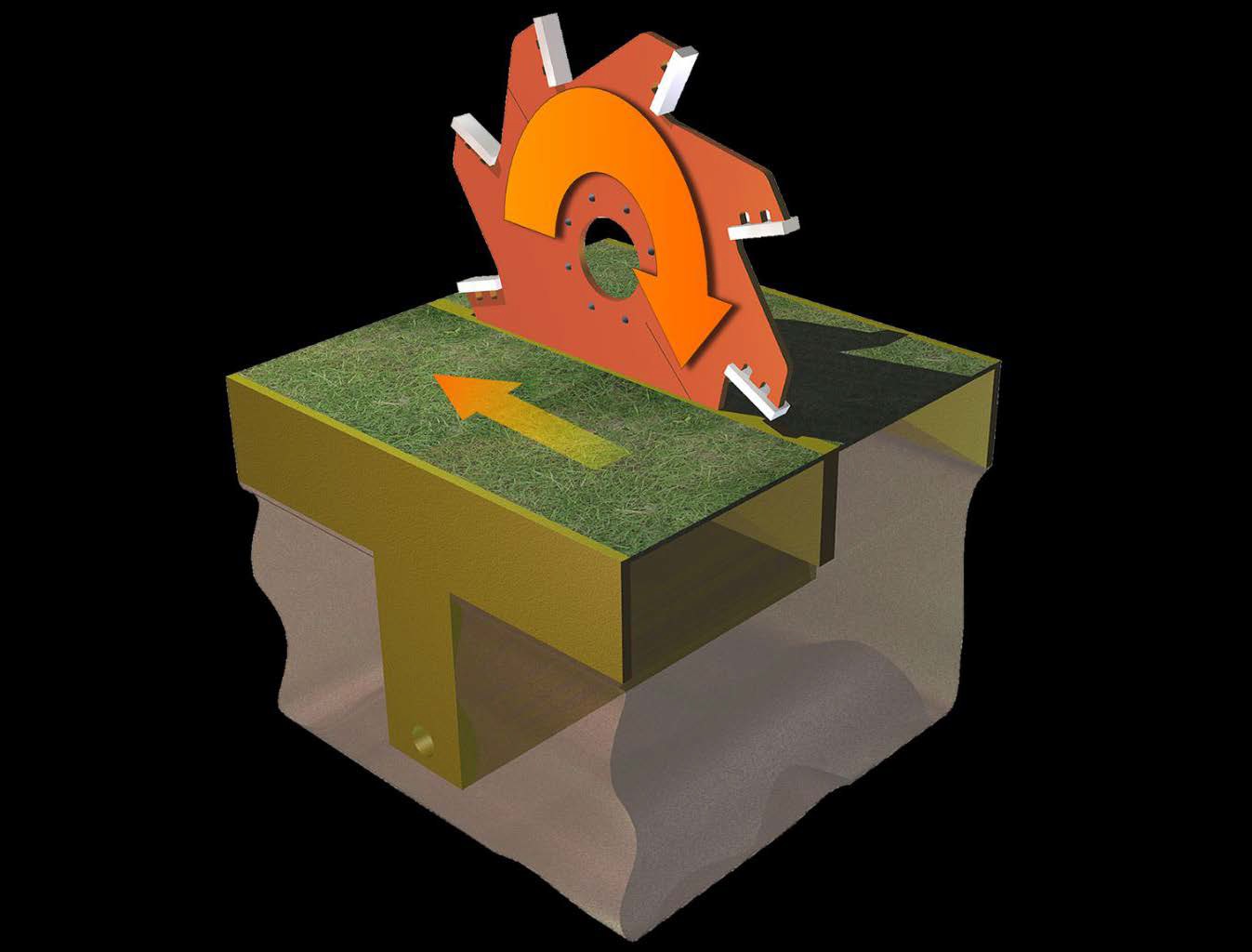

The machine mills 2 or 3 trenches of 4 cm wide, perpendicular to the existing drainage system. The milled material is discharged via the conveyor belt to a collecting container driven by yout parallel driver. You can reuse this as a dress ground. The Drainmaster then fills the trenches with drain sand as desired, from the sand bunker. Lastly the rear wheels of the machine push the sand into the trench.

The Drainmaster has been in continuous development since 1985. Over the years, the concept has been further refined. The system is designed to improve and accelerate the drainage of surface water, increasing the stability and quality of the grass stock. The result of working with the Drainmaster? In a few weeks, the grass will grow over the sand trenches again. This results in better drainage due to a stronger grass stock. In this way you increase the playing capacity of the sports turf and minimize play damage. Now your field can last for years to come! For an optimal result, choose the combination with the Combinator, so that your field is also nicely even.

Specification

- 2 or 3 parallel cutters (with a working width of 85 cm or 150 cm respectively).

- Working depth of no less than 23 cm.

- 1x double-acting hydraulic valve depth control articulated.

- 2x double acting hydraulic valve clinder side tire and wheel set.

Drainmaster Knives

- The knives are made of carbon steel with a tungsten tip

- Knife blade width: 4 cm

- Max working depth: 23cm

- Three section knives with a total working width of 150cm

- The organic material is thrown onto a conveyor belt for collection

Drainmaster Hydraulics and Sand Container

- The conveyor belt is controlled from inside the cab

- Knife rotor is controlled from the cab by the gearbox

- The dosing valves for the amount of sand are controlled from the cab

Drainmaster Results

First GKB Drainmaster entered service in 1985 it has been constantly updated since then and the solid build quality of this machine guarantees many years of enjoyment.

The result after working with GKB Drainmaster is an even dosage of sand throughout the depth of your slot drainage

The result after working with GKB Drainmaster is an even dosage of sand throughout the depth of your slot drainage

Drainmaster Option

As an option for GKB Drainmaster there is a Heavy duty kit with more durable blades.

Why GKB

The machines that we develop are reliable, robust machines. We owe this fact to the fact that we are still working with the machines as well. We know what the man who does the work requires to operate in a good and efficient manner. Therefore, we are using a new slogan: “The Worker is King”. This is important, since only in this way the machine can deliver pitches that look great. The reason why you should purchased it.

GKB sustainability

At GKB Machines we feel strongly about sustainability, as a family-owned company we aim for a sustainable company with a positive future prospect. That we do not just stick to words is evident from the fact that we are producing our machines energy neutral.

Sustainability is also highly important during the development of the machines. We develop the machines from the experience we have established from our contractor division. Every GKB Machine must satisfy the high-quality requirements that we impose. A sustainable, reliable and robust machine is the foundation for your operation. Since our contractor division is used to receiving these type of machines, you might also expect this from us.

GKB Machines is part of the GKB Group. Since 1985 GKB Machines, as a separate division, is engaged with the development of innovative maintenance machines for sports pitches.

Sustainability is also highly important during the development of the machines. We develop the machines from the experience we have established from our contractor division. Every GKB Machine must satisfy the high-quality requirements that we impose. A sustainable, reliable and robust machine is the foundation for your operation. Since our contractor division is used to receiving these type of machines, you might also expect this from us.

GKB Machines is part of the GKB Group. Since 1985 GKB Machines, as a separate division, is engaged with the development of innovative maintenance machines for sports pitches.

-

Working width 1500 mm

-

Working depth 0-230 mm

-

Hopper capacity 4000 l

-

PTO power requirement >120 hkr

-

Creeper gear required

-

Hitching Towing eye

-

Hydraulic valves required from tractor 3xDA

Draining

GKB Machines is part of the GKB Group. Since 1985 GKB Machines, as a separate division, is engaged with the development of innovative maintenance machines for sports pitches.

GKB Machines feel strongly about sustainability, as a family-owned company they aim for a sustainable company with a positive future prospect. That they do not just stick to words is evident from the fact that they are producing the machines energy neutral.

Sustainability is also highly important during the development of the machines. GKB develop the machines from the experience they have established from their contractor division. Every GKB Machine must satisfy the high-quality requirements that they impose. A sustainable, reliable and robust machine is the foundation for your operation. Since their contractor division is used to receiving these type of machines, you might also expect this from GKB.

"The Worker is King"

The machines that GKB develop are reliable, robust machines. They owe this fact to the fact that they are still working with the machines as well. GKB knows what the man who does the work requires to operate in a good and efficient manner. Therefore, they are using a new slogan: “The Worker is King”. This is important, since only in this way the machine can deliver pitches that look great. The reason why you purchased it.

GKB Machines feel strongly about sustainability, as a family-owned company they aim for a sustainable company with a positive future prospect. That they do not just stick to words is evident from the fact that they are producing the machines energy neutral.

Sustainability is also highly important during the development of the machines. GKB develop the machines from the experience they have established from their contractor division. Every GKB Machine must satisfy the high-quality requirements that they impose. A sustainable, reliable and robust machine is the foundation for your operation. Since their contractor division is used to receiving these type of machines, you might also expect this from GKB.

"The Worker is King"

The machines that GKB develop are reliable, robust machines. They owe this fact to the fact that they are still working with the machines as well. GKB knows what the man who does the work requires to operate in a good and efficient manner. Therefore, they are using a new slogan: “The Worker is King”. This is important, since only in this way the machine can deliver pitches that look great. The reason why you purchased it.