Save on costs by turning leaves into nutrients with the LeafReducer 150!

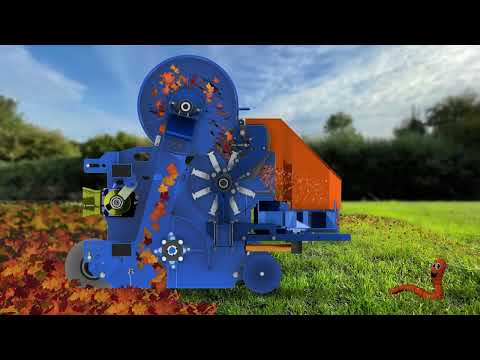

GKB's Leaf Reducer is a 100% sustainable method that converts leaf waste into nutrients. The leaves are ground down and spread out, allowing decomposition to start immediately. Eliminate the costs of waste disposal and transportation while ensuring a significant reduction in CO2 emissions. This method can be used in urban areas, such as parks and lawns. The working height is adjustable, making it suitable for areas with both short and tall grass. The outflow is controlled by the hydraulically driven disc unit behind the machine. The spreading pattern can be adjusted directly behind the machine, to the left or to the right, to suit the area you are working in.

GKB's Leaf Reducer is a 100% sustainable method that converts leaf waste into nutrients. The leaves are ground down and spread out, allowing decomposition to start immediately. Eliminate the costs of waste disposal and transportation while ensuring a significant reduction in CO2 emissions. This method can be used in urban areas, such as parks and lawns. The working height is adjustable, making it suitable for areas with both short and tall grass. The outflow is controlled by the hydraulically driven disc unit behind the machine. The spreading pattern can be adjusted directly behind the machine, to the left or to the right, to suit the area you are working in.

Smart and environmentally friendly

- No waste transportation costs.

- Up to 65% CO2 reduction.

- Immediate decomposition.

- Free nutrients for the grass.

The methods the LR150 uses:

The leaves are scooped up with flails and then sucked up further by the turbine. The turbine ensures that the blade is reduced the first time. After this, the leaf is thrown into the hammer mill, where the leaf is shredded into a fine mulch. The built-in safety mechanism ensures that hard materials such as stones can leave the machine. After shredding, the leaf is thrown onto the disc unit

The environmentally friendly choice

For municipalities and environmentally conscious businesses, the GKB LeafReducer is an excellent choice. Here is a comparison of carbon dioxide emissions per hectare for various leaf removal methods:

LeafReducer from GKB: 80 kg CO2/ha

The use of LeafReducer results in low emissions because leaves are reused as compost.

Leaf blowers and leaf vacuums + compost spreading: 265 kg CO2/ha

Traditional leaf blowers and leaf vacuums, combined with compost spreading, generate high emissions, both in transporting leaves and in the production, transport, and spreading of compost.

Leaf blowers and leaf vacuums: 175 kg CO2/ha

Using only leaf blowers and leaf vacuums still results in relatively high emissions due to leaf transportation.

GKB LeafReducer is the superior choice for reducing environmental impact and contributing to a more sustainable future, all while meeting high environmental standards.

LeafReducer from GKB: 80 kg CO2/ha

The use of LeafReducer results in low emissions because leaves are reused as compost.

Leaf blowers and leaf vacuums + compost spreading: 265 kg CO2/ha

Traditional leaf blowers and leaf vacuums, combined with compost spreading, generate high emissions, both in transporting leaves and in the production, transport, and spreading of compost.

Leaf blowers and leaf vacuums: 175 kg CO2/ha

Using only leaf blowers and leaf vacuums still results in relatively high emissions due to leaf transportation.

GKB LeafReducer is the superior choice for reducing environmental impact and contributing to a more sustainable future, all while meeting high environmental standards.

-

Working width 1500 mm

-

PTO power requirement >60 hkr

-

Spreading device Hydraulically driven debris distributor

-

Rotor drive PTO

-

Linkage Standard three-point hitch cat. I-II

-

Hydraulic valves required 2xDA

Leaf removal equipment

GKB Machines is part of the GKB Group. Since 1985 GKB Machines, as a separate division, is engaged with the development of innovative maintenance machines for sports pitches.

GKB Machines feel strongly about sustainability, as a family-owned company they aim for a sustainable company with a positive future prospect. That they do not just stick to words is evident from the fact that they are producing the machines energy neutral.

Sustainability is also highly important during the development of the machines. GKB develop the machines from the experience they have established from their contractor division. Every GKB Machine must satisfy the high-quality requirements that they impose. A sustainable, reliable and robust machine is the foundation for your operation. Since their contractor division is used to receiving these type of machines, you might also expect this from GKB.

"The Worker is King"

The machines that GKB develop are reliable, robust machines. They owe this fact to the fact that they are still working with the machines as well. GKB knows what the man who does the work requires to operate in a good and efficient manner. Therefore, they are using a new slogan: “The Worker is King”. This is important, since only in this way the machine can deliver pitches that look great. The reason why you purchased it.

GKB Machines feel strongly about sustainability, as a family-owned company they aim for a sustainable company with a positive future prospect. That they do not just stick to words is evident from the fact that they are producing the machines energy neutral.

Sustainability is also highly important during the development of the machines. GKB develop the machines from the experience they have established from their contractor division. Every GKB Machine must satisfy the high-quality requirements that they impose. A sustainable, reliable and robust machine is the foundation for your operation. Since their contractor division is used to receiving these type of machines, you might also expect this from GKB.

"The Worker is King"

The machines that GKB develop are reliable, robust machines. They owe this fact to the fact that they are still working with the machines as well. GKB knows what the man who does the work requires to operate in a good and efficient manner. Therefore, they are using a new slogan: “The Worker is King”. This is important, since only in this way the machine can deliver pitches that look great. The reason why you purchased it.