Optimize efficiency during harvest with Krone BaleCollect!

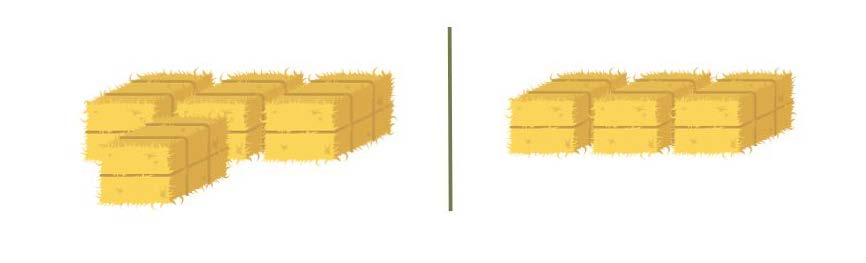

A bale collector can significantly streamline your harvest, especially when paired with a large bale press. This model can collect up to three square bales that are 120 cm wide or five bales that are 80 cm wide. This makes it easier to save time, reduce costs, minimize soil compaction, and achieve high productivity during harvest.

A bale collector can significantly streamline your harvest, especially when paired with a large bale press. This model can collect up to three square bales that are 120 cm wide or five bales that are 80 cm wide. This makes it easier to save time, reduce costs, minimize soil compaction, and achieve high productivity during harvest.

Save time retrieving bales

BaleCollect is designed to streamline the process of gathering and arranging square bales efficiently. With a hydraulic telescopic drawbar and automated bale handling, it minimizes the need for manual operation. It can collect up to three or five bales simultaneously, and the various deposition modes facilitate reducing the time spent retrieving bales from the field, whether they are for loading onto a wagon or for silage baling.

Customize settings to suit your needs

Krone BaleCollect offers a new GPS-guided feature that simplifies bale handling. By using pre-programmed virtual lines, the machine can automatically deposit bales in the desired pattern from five different options in straight rows. This minimizes field traffic and optimizes bale collection.

Reduced fuel costs

By reducing the number of trips required to transport bales from the field to the wagon or storage area, BaleCollect lowers fuel costs. Additionally, the integrated weighing system allows for optimizing transport logistics and bale management, further reducing unnecessary expenses.

Minimized field compaction

BaleCollect features a wide platform that evenly distributes the weight of the bales it handles over the ground. This results in significantly reduced field compaction, promoting soil health and preserving fertility. Fewer passes also mean less soil compaction, contributing to the preservation and improvement of soil structure over time. This, in turn, increases yields and reduces the need for costly soil restoration.

Smooth bale handling

As the bales leave the press chamber and approach BaleCollect, they pass a sensor that triggers a signal, causing the bales on the platform to be pushed aside using a bar. It's only after the last bale has landed on the collector that all bales are discharged, streamlining the collection process.

Smart coupling mechanism

The bale collector is connected to the press to gather bales as they leave the press chamber. It connects to the press using a hydraulic telescopic drawbar developed by Krone to ensure safe road transport. The telescopic drawbar extends hydraulically during transport, and the wheel axles lock for a more agile transport. In the field, the drawbar contracts, and the wheels disconnect to become self-steering pivot wheels.

GPS-guided automatic bale deposition

The new GPS-guided feature in Krone BaleCollect significantly simplifies bale handling. By using pre-set virtual lines, the machine can automatically deposit bales at right angles along the designated lines. The principle behind Krone BaleCollect is as follows: the machine first travels around the field and registers up to five lines along which the bales will be automatically deposited. The most significant advantage of this technology is that it places the bales in the opposite direction of travel along the pre-programmed lines, optimizing bale collection and minimizing unnecessary field traffic.

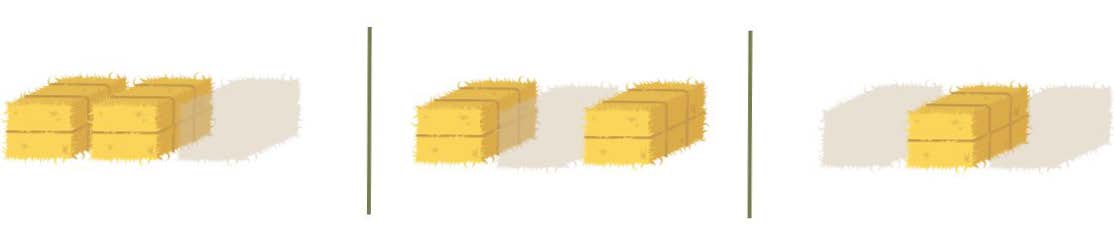

Deposition near field edges

The '3 bales' and '3+1 bales' modes are employed to deposit all bales near the field edge. With these strategies, you can efficiently and swiftly remove bales from the collector.

For silage bales to be wrapped

The '2 bales side by side' and '2 bales apart' modes are used for silage bales where the following wrapper either wraps two silage bales simultaneously or picks up the bales on its own.

Manual control of deposition

The operator can also manually release bales at any time by simply pressing a button, providing the flexibility to adapt deposition to unique workflows.

Safe and agile road transport

When it's time for road transport, the collector's sides fold hydraulically to less than 3 meters. Krones BiG Pack models are equipped with a braking system adapted to handle the additional weight of the collector, enabling safe transport even in hilly terrain at speeds of up to 50 km/h.

Control two machines from a single terminal

With BaleCollect, it's easy to connect to the ISOBUS system, which is now standard on Krones BiG Pack models. This means both the baler and the collector can be controlled from a single operator terminal with a clear and user-friendly menu and intuitive navigation. The CCI 1200 terminal displays both user interfaces along with the camera feed, providing the operator with a perfect overview. BaleCollect can also be controlled from either the Beta II or Delta terminal or from the tractor's existing terminal.

Weigh bales on-the-go

If the BaleCollect is connected to ISOBUS, all bales can be individually weighed by the collector. It features a weighing system that individually weighs each bale and is linked to an acceleration sensor, increasing weighing accuracy by filtering out vibrations and shocks to a margin of error of only +/- 2%.

For over 100 years, KRONE has been a reliable manufacturer of modern forage machinery from Germany. Today, their product range includes premium machinery for forage harvesting, including balers, mowers, tedders, rakes, balers, and self-propelled forage harvesters.

KRONE is a family-owned company that delivers reliable, high-quality, and durable machinery with the goal of increasing customer productivity. They provide extensive training programs for their service personnel and maintain a large database to simplify troubleshooting and support.