Powerful and fuel-efficient BiG M 450 CV - a self-propelled mower conditioner designed for all conditions!

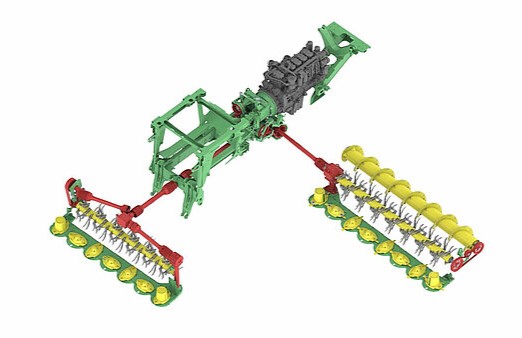

This machine is the ultimate solution for those dealing with demanding mowing conditions, aiming for high productivity, safety, and comfort. With its robust engine and wide 9.90 m working width, it's a reliable partner for maximizing harvest results, minimizing effort, and covering vast areas in a short time.

This machine is the ultimate solution for those dealing with demanding mowing conditions, aiming for high productivity, safety, and comfort. With its robust engine and wide 9.90 m working width, it's a reliable partner for maximizing harvest results, minimizing effort, and covering vast areas in a short time.

Efficient, user-friendly and versatile

With its powerful and fuel-efficient engine and an impressive working width, the BiG M is designed to easily cover large areas with high efficiency, saving resources and reducing costs. It features an ergonomically designed cabin and agility that makes it the optimal choice, regardless of terrain conditions. The hydropneumatic suspension on the axles ensures outstanding operator comfort during long work sessions. Furthermore, it offers exceptional maneuverability, excellent visibility, and intuitive user interfaces, making it the superior choice for forage harvesting.

Simplified mowing, even in hilly terrain

Whether you're working on large or small fields, flat or hilly terrain, or even in the most challenging soil conditions, this is the perfect machine. It's specially designed to make mowing as simple and safe as possible, even in demanding terrains. With this machine, you can be confident that it delivers high productivity and performance while ensuring comfort during work.

Let technology assist you in achieving top-notch forage!

Spotting all the obstacles hiding in the forage can be challenging. That's why this machine is equipped with collision protection called SafeCut, which shields the machine from damage caused by rocks or branches. The integrated support arm protection reacts swiftly, halting affected cutter discs to minimize downtime and get back to work promptly. This system can save you costly and time-consuming repairs, especially when timing is crucial to getting top value for your feed.

Your best friend in forage harvest: reliable machinery!

Reliable machines are invaluable for a smooth forage harvest. The BiG M requires minimal maintenance and features an automatic lubrication system that reduces wear and tear, allowing you to focus more on the harvest while saving money. The engine only requires maintenance every thousand operating hours or once a year, making maintenance tasks simple even during the harvest. Farmers First Maintenance app provides ready-made maintenance plans, contributing to reduced downtime, increased lifespan, and improved resale value.

Work capacity of over 17 hectares per hour

The BiG M is equipped with an innovative driveline that enables work capacities of over 17 hectares per hour. The axially mounted engine's power is directly transmitted via power bands and drive shafts to the three cutting units. This direct power transfer ensures high efficiency and reliable performance. Hydraulic adjustment of the cutter bar height and complete ground pressure control from the cabin enhances your comfort and allows for precise and efficient management of large areas, reducing fatigue and increasing productivity.

Simple and smooth maneuvering

Not all fields are easy to mow, as narrow spaces and challenging terrains can affect productivity. That's why the BiG M is equipped with wheel motors and the ability to pivot up to a 50-degree angle. This feature makes the machine extremely agile and easy to maneuver, increasing efficiency, especially in small fields and demanding terrains. Aside from saving time and achieving higher productivity, it also reduces the risk of crop and machine damage.

Maximum operator comfort

All axles on the BiG M are equipped with hydraulic height adjustment and hydro-pneumatic suspension, providing operators with unparalleled riding comfort in both the field and on public roads. For example, they can lower the chassis to achieve a transport height of less than 4 meters. This ensures maximum comfort and simplifies the transition between different work sites and road transport. Additionally, the engine and transmission are mounted on vibration-damping blocks, ensuring quiet operation and reduced noise levels.

Powerful engine

The BiG M is equipped with a powerful Liebherr engine that meets Stage V emissions standards. This engine uses Selective Catalytic Reduction (SCR) technology to ensure clean and efficient combustion. By injecting urea into the exhaust stream, nitrogen oxides are converted into natural nitrogen and water, minimizing environmental impact. With a 780-liter fuel tank and an 80-liter urea tank, you can work long days without interruption, increasing your productivity and saving time and money.

Lower fuel costs

The BiG M is equipped with PowerSplit engine control that carefully monitors engine speed to adjust performance as needed. In Eco mode, the engine starts at 1650 rpm, delivering 354 hp, providing sufficient power for routine tasks. But when extra power is required, it automatically switches to M mode with 449 hp to handle more demanding tasks. Additionally, Load Limit Control is activated if the engine speed drops too much to ensure smooth operation. This intelligent system means the machine automatically adapts its performance to the workload, significantly reducing fuel consumption.

Automatic speed control for better results

The BiG M is equipped with a smart feature that adjusts the machine's speed automatically during work. It adapts the speed based on working conditions and adjusts the ground speed accordingly. If the machine needs to mow more precisely, it slows down automatically, which is particularly valuable in challenging terrain, while it increases speed when possible to enhance efficiency. With automatic speed control, you no longer need to worry about manual speed adjustments, saving time and ensuring the quality of your work.

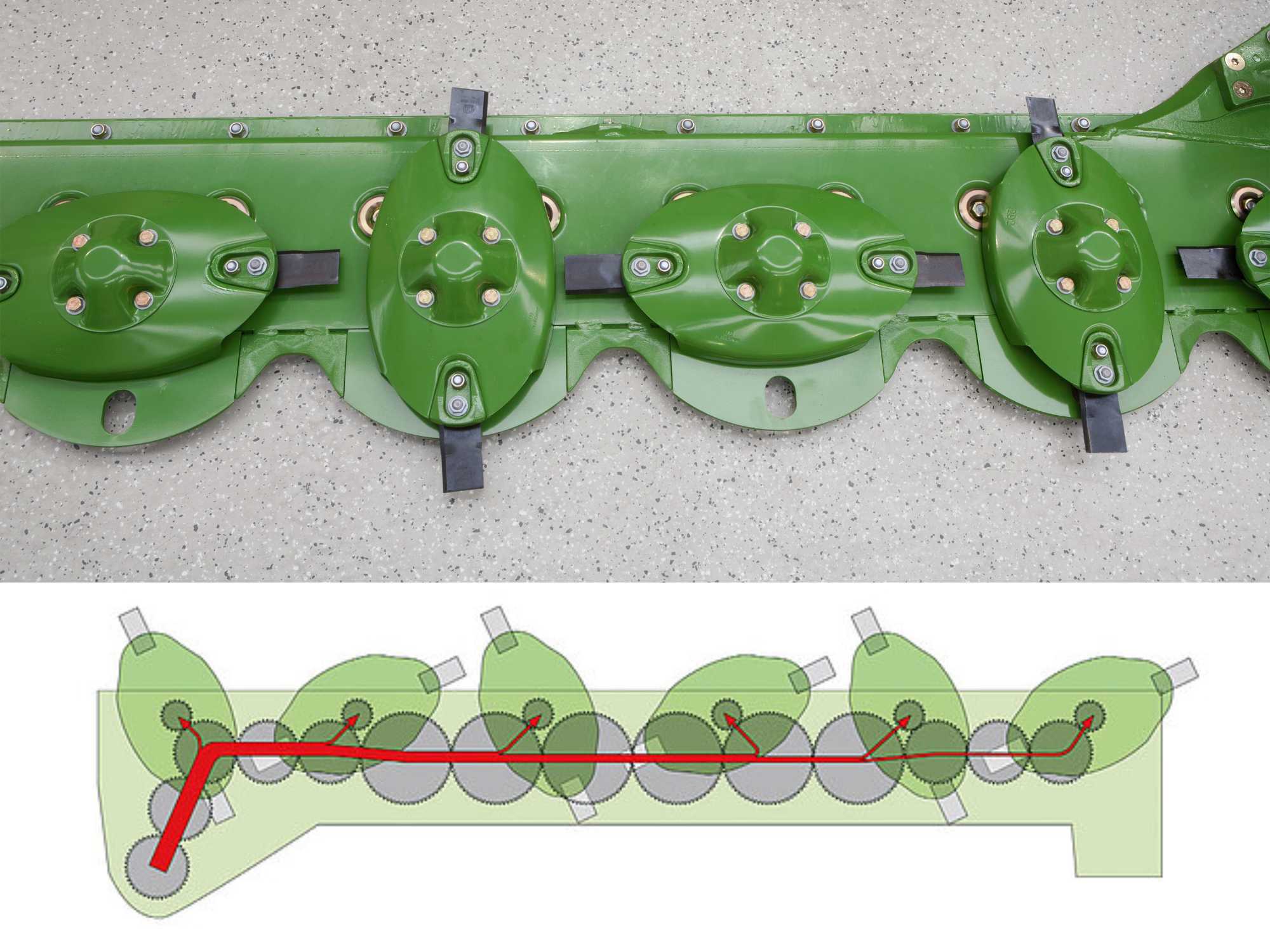

Simplified and faster blade change system

The key to clean cuts is quality blades, which is why Krone has developed a blade change system that is both simple and fast. This ensures that you can always achieve results with clean cuts in the field, promoting healthy and rapid regrowth. When it's quick to change the blades, it becomes easier to do so as often as needed, ensuring optimal performance of the mower.

Maximum regrowth with gentle cutterbar

In order for the pasture to recover and grow rapidly after the first cut, a gentle initial mowing is required. The Krone cutterbar is the heart of the machines and is built to last, with a robust welded construction and permanent lubrication. Its massive gears impress with quiet and reliable operation under continuous load, contributing to superior cutting quality and maximum longevity.

Safe field cutting and quick field repairs with SafeCut

Avoiding stones and branches hidden in the field can be challenging. That's why Krone equips its mowers with the SafeCut system, safeguarding your machine from unexpected obstacles, reducing downtime, and repair needs. SafeCut's unique features, such as pins that release under overload and self-lifting discs, prevent chain reactions and simplify on-field repairs. With this collision-resistant design and wear-resistant components, Krone's SafeCut system ensures a secure forage harvest.

Smooth cuts on slopes and curves

To avoid uneven cuts on curves and sloping fields, there's an optional side-shift function for the front mower unit. Using a sensor that detects the current steering angle, the mower unit can move hydraulically to the right or left in relation to the wheel's current position. This function eliminates the risk of uneven cuts and streaks in curves or on sloping fields, resulting in a smooth and high-quality cut. This, in turn, can improve the harvest and increase yield.

High productivity and outstanding conditioning with CV rollers

The CV rotor, with V-shaped and grippy steel tines, ensures even distribution of the crop across the entire working width. Its robust Ø64 cm and spiral tooth arrangement guarantee uninterrupted crop flow, high productivity, and outstanding conditioning. The V-tines are made of hardened steel and mounted at a steep angle, providing intensive and powerful forage treatment. The tines pivot rearward upon encountering foreign objects, while forward pivoting is restricted to extend the pin's service life.

A cabin with optimal visibility and comfort

The cabin of the BiG M has large windows that provide excellent visibility from all angles and maximum comfort during long workdays. Here, you'll find an 8-inch or 12-inch touchscreen where you can easily configure and monitor the machine's functions. The ergonomic joystick is integrated into the armrest of the driver's seat, providing fingertip control over all machine functions with clearly marked controls.

Smooth ground pressure adjustment for optimal quality

Now you can easily manage ground pressure and cutting height directly from the cabin. Program two different cutting heights and ground pressure settings into the system and select your desired configuration with a joystick control. The DuoGrip function ensures even ground pressure across the entire working width. The side mowers are suspended in ball sockets in a center-of-gravity-based system, providing ample freedom of movement and ensuring clean cuts on sloping fields and along ditches and road edges. This saves time and increases your yield through reliable results.

Efficient handling of large crop volumes!

Being able to choose between swath formation and wide crop spreading is essential for adapting to different conditions. As an option, this model can be equipped with optional augers that direct all material to the swath from the front mower unit when they're closed, ensuring no forage goes to waste and that it is placed in a swath. When open, the crop is evenly and loosely spread over the working area for efficient drying. The settings are controlled from the cabin and are saved, so they open or close automatically when the cutting units are activated. The improved augers have 20% larger auger blades, allowing for the handling of larger crop volumes with increased gent

Optimal performance and ground following, even in rocky fields!

The BiG M is equipped with extra-wide skids that minimize ground pressure and protect the cutter bar from damage. These skids are made of hardened steel, making them incredibly durable and ensuring a smooth feed of forage while protecting the grass surface. The skids play a crucial role in keeping the cutter bar parallel to the ground, resulting in exceptional stubble height precision. To handle different terrains and cutting heights, various skid options are available, including wear protection and those suitable for high-cutting.

Generous ground clearance, even in high yielding crops

Since the BiG M has individual wheel motors, there's no need for axles close to the ground. Additionally, hydraulic cylinders automatically raise the machine's chassis by 15 cm in field mode, providing generous ground clearance for working in high-yielding crops. This ensures you can handle your work smoothly even in demanding conditions, increasing efficiency and productivity in your operations.

Designed to last

This machine is equipped with a sensor-controlled automatic lubrication system that ensures lubrication is performed at most lubrication points. This not only minimizes wear and extends the machine's lifespan but also leaves more time for operation during the harvest season. Additionally, it has impressive service intervals - only every 1,000 hours or once a year!

Efficient radiator cleaning

The BiG M features an active radiator cleaning technology - a rotating fine-mesh screen that keeps debris away from the radiator. The rotating screen passes through a fan that removes debris from its surface. The generously sized unit ensures that the engine temperature always remains within the optimal range. This contributes to maintaining the machine's performance and reliability.

Improved machine safety with collision protection system!

Integrated into the suspension system, the standard collision protection system is available on all supported mowing units. The collision protection system provides peace of mind when working alongside boundaries, fences, and hedges, and suddenly encountering an obstacle. When the system triggers a collision, the mower bar swings backward and upward to clear the obstacle. Once the obstacle is passed, the mower bar automatically returns to the working position. The conventional mechanical collision protection is a highly reliable system consisting of an adjustable coil spring and a lock.

Fast and safe transportation

The BiG M offers fast and secure transportation between work sites, reaching up to 25 km/h in the field and 40 km/h on roads while efficiently reducing the engine speed to 1250 rpm for fuel savings. Operator comfort is a priority with hydro-pneumatic suspension on both axles, and the machine can be hydraulically lowered by up to 15 cm to achieve a transport height of less than four meters. This saves time and resources while increasing productivity and streamlining the harvesting process.

Easy maintenance

Maintenance is more enjoyable when it's straightforward, which is why the BiG M has a wide hood that provides easy access to the engine for service and inspection. It also has ample storage space for tools and spare parts, making it easy to keep everything you need close at hand. With large fuel tanks of 780 liters and 80 liters of urea, you won't need to refuel as often, and refilling is easily accessible via secure steps and a platform. All of this is designed to make your maintenance as simple and efficient as possible.

Additional options

-

Type of machine Selfpropelled mower conditioner with CV conditioner.

-

Number of mowing units 3

-

Capacity fueltank 780 l

-

Capacity DEF tank 80 l

-

Working width 9.90 m

-

Transport width 3.00 m

-

Transport length 8.45 m

-

Transport height 4.00 m

-

Weight 16000 kg

-

Weight distribution front/ rear axle 64/36 %

-

Number of discs/ unit 6 / side mounted mower, 5 / front mounted mower

-

No. of swathing drums/ unit 2 / side mounted mower, 2 / front mounted mower

-

Quickchange system knifes

-

Discprotection

-

Skids Yes, as option

-

Conditioner unit

-

Type of conditioner V-type steel tines

-

Conditioner speed 700, 1000 rpm

-

Swathing Merger augers and hydraulically controlled merger auger hoods.

-

Engine type Liebherr D946 A7-05

-

Capacity, nmbrs of cylinders 12L/ 6

-

449 hkr

-

330 kw

-

Max work rate Max. 25 kmh

-

Transport speed 40 kmh

-

4WD std

-

Traction Control std

-

Max. steering angle 53 degree

-

-

Hydro-pneumatic

-

Front tire std Mitas AC 70 N 800/65 R 32

-

Rear tires std Mitas AC 65 600/65 R28

-

Front tyres option Vredestein Flotation Trac 800/60 R 32

-

Rear tyres option Vredestein Flotation Trac 600/60 R 30.5

-

Airseat

-

Instructor seat

-

Automatic climate control

-

Information system

-

Fridge in cabin

General

Dimensions

Cutterbar

Conditioner

Engine

Wheels

Drivers Cabin mover

For over 100 years, KRONE has been a reliable manufacturer of modern forage machinery from Germany. Today, their product range includes premium machinery for forage harvesting, including balers, mowers, tedders, rakes, balers, and self-propelled forage harvesters.

KRONE is a family-owned company that delivers reliable, high-quality, and durable machinery with the goal of increasing customer productivity. They provide extensive training programs for their service personnel and maintain a large database to simplify troubleshooting and support.